Make Certain Optimum Efficiency: Picking the Right Komatsu Undercarriage Parts for Your Fleet

Make Certain Optimum Efficiency: Picking the Right Komatsu Undercarriage Parts for Your Fleet

Blog Article

Reliable Solutions: Undercarriage Parts for Heavy Machinery

When it concerns hefty equipment, the undercarriage is an important element that frequently determines the total performance and performance of the equipment. Quality undercarriage components play a considerable role in making certain the smooth procedure and longevity of hefty machinery. From excavators to dozers, each tool relies greatly on its undercarriage to stand up to difficult working problems. However, deterioration are unavoidable, bring about prospective issues that can impede productivity and rise maintenance prices (komatsu undercarriage parts). In this discussion, we will certainly explore the value of purchasing superior undercarriage parts, typical wear obstacles dealt with by hefty machinery drivers, the benefits of prompt substitutes, guidelines for choosing reliable vendors, and important upkeep tips to prolong the life-span of undercarriage elements.

Value of Top Quality Undercarriage Components

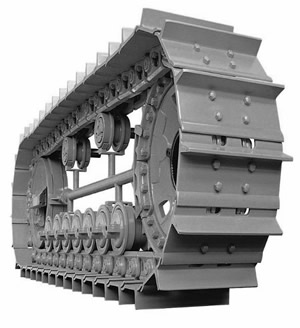

Quality undercarriage components are essential components in guaranteeing the toughness and efficiency of heavy equipment. The undercarriage of tools such as excavators, excavators, and track loaders plays a crucial role in supporting the device's weight, offering stability on various terrains, and absorbing the impact of uneven surface areas. By buying high-grade undercarriage components, drivers can dramatically expand the life expectancy of their machinery and decrease the risk of unexpected breakdowns.

One trick advantage of making use of high quality undercarriage parts is the enhancement of total equipment efficiency. Resilient tracks, idlers, gears, and rollers minimize friction and guarantee smoother activity, eventually resulting in raised efficiency and performance on task sites. Reputable undercarriage components decrease downtime for maintenance and repairs, permitting operators to optimize their operational hours and task deadlines.

Usual Undercarriage Use Problems

Advantages of Timely Substitute

One key benefit of prompt undercarriage component substitute is boosted device uptime. By replacing worn components prior to they stop working, the danger of unexpected break downs is minimized, reducing downtime for repairs and upkeep. This positive method not only maintains the hefty machinery functional however likewise stops prospective damage to various other elements that could arise from a stopping working undercarriage.

Furthermore, replacing undercarriage components quickly can enhance total performance. A properly maintained undercarriage guarantees optimal maker performance, permitting for smoother operation and higher effectiveness in completing jobs. This, in turn, brings about boosted job website productivity and price savings by staying clear of delays and disturbances brought on by underperforming equipment. Investing in prompt undercarriage component replacement is an aggressive technique that pays off in terms of enhanced performance and decreased operational costs.

Picking the Right Undercarriage Supplier

Selecting the ideal undercarriage vendor is a vital decision that dramatically affects the performance and upkeep of heavy machinery. When picking a vendor for undercarriage parts, a number of aspects need to be considered to guarantee ideal effectiveness and cost-effectiveness. A provider that supplies a broad selection of undercarriage components for various hefty machinery brand names and designs can be beneficial as it gives much more alternatives to satisfy specific requirements.

Additionally, reviewing the provider's customer care and assistance is critical. A vendor that offers exceptional customer support, fast response times, and technical aid can help lessen downtime and ensure smooth operations. Price is also a considerable variable to consider; nevertheless, it needs to not be the sole factor. When picking the appropriate undercarriage supplier for heavy machinery, balancing top quality, cost-effectiveness, and integrity is essential. By very carefully examining these aspects, you can select a vendor that satisfies your demands and adds to the effective performance and maintenance of your heavy machinery.

Upkeep Tips for Extended Lifespan

To make sure a prolonged life-span for you can try these out hefty machinery undercarriage parts, carrying out an aggressive upkeep routine is vital. Investing in high quality undercarriage components from reputable suppliers is equally essential for guaranteeing durability. By complying with these upkeep ideas carefully, hefty equipment owners can enhance the performance and sturdiness of their undercarriage parts, ultimately decreasing downtime and operational prices.

Verdict

In verdict, top quality undercarriage components are necessary for the reliable operation of heavy machinery. Prompt substitute of used parts can prevent costly downtime and keep ideal performance. Choosing a reliable vendor and adhering to correct maintenance practices are official website vital to making certain the prolonged lifespan of undercarriage components. By resolving typical wear issues and purchasing top notch parts, hefty equipment operators can take full advantage of productivity and decrease upkeep costs.

Too much wear and tear on undercarriage components of heavy machinery can lead to substantial functional difficulties and enhanced upkeep expenses. Routine inspections, correct upkeep, and timely substitutes of used undercarriage parts are essential to minimize these typical wear problems and click to investigate make certain the ideal functioning of hefty machinery.

A supplier that uses a broad choice of undercarriage components for various heavy machinery brand names and versions can be advantageous as it gives more options to fulfill particular demands.

By complying with these maintenance ideas vigilantly, hefty machinery proprietors can optimize the efficiency and sturdiness of their undercarriage components, eventually lowering downtime and operational prices.

Report this page